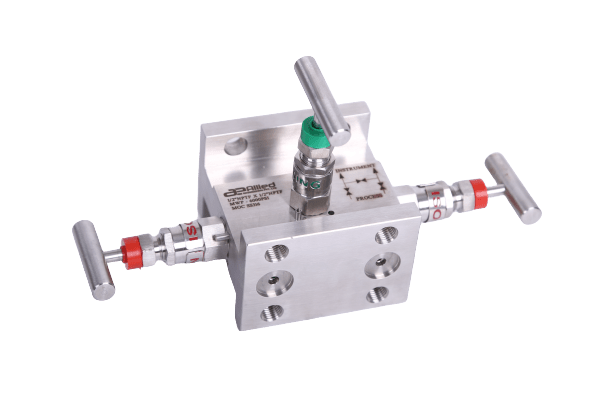

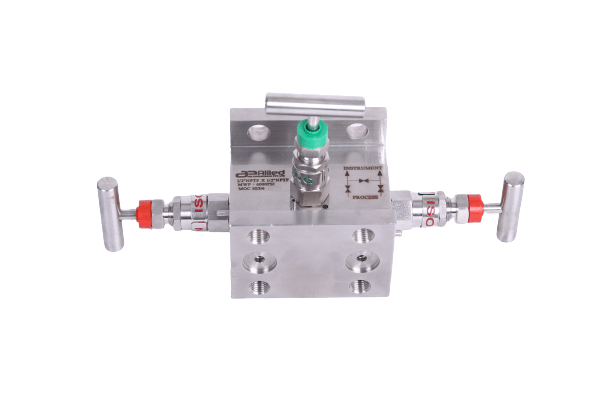

Model No. A3VMH

Designed for direct or remote mounting of

differential pressure transmitters. For remote mounting two oval / kidney

flanges are used for connecting process pipe to manifold block. The manifold

block incorporate two main valves for process isolation and one valve for

equalizing.

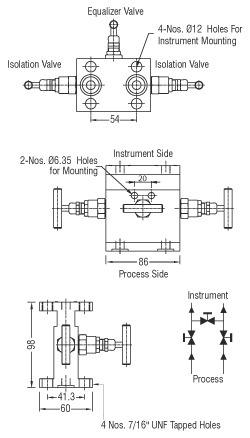

Dimensions shown are for the standard 54 mm or 2 1/8 inch instrument connection Centre distance found in majority of instruments. The manifold is also available for instruments with other centre distances for instrument connections (as 55 mm, 56 mm and 57 mm) but dimensions shown will vary. Please consult us for these dimensions.

Dimensions shown are for the standard 54 mm or 2 1/8 inch instrument connection Centre distance found in majority of instruments. The manifold is also available for instruments with other centre distances for instrument connections (as 55 mm, 56 mm and 57 mm) but dimensions shown will vary. Please consult us for these dimensions.

Flanged instrument and process connection

Description

Connection

Process : Flanged

Instrument : Flanged

Drain/Vent : 1/4″ NPT (F) optional

Instrument : Flanged

Drain/Vent : 1/4″ NPT (F) optional

Test Pressure

@ 25°C Room Temperature

Hydrostatic : Body – 415 bar(g)

Seat – 415 bar(g)

Pneumatic : Seat – 7 bar

Hydrostatic : Body – 415 bar(g)

Seat – 415 bar(g)

Pneumatic : Seat – 7 bar

Gland Packing

PTFE : Standard

GRAPHOIL : Temperatures above 200°C

GRAPHOIL : Temperatures above 200°C

Material

A 105, A 182 GR F 304, A

182 GR F 316, Monel, Hastelloy, Duplex

Finish

CS zinc plated, SS Natural

Accessory

Two PTFE seal ring and four

7/16” UNF HI Steel mounting bolts available on request

Mounting Kit

Mounting bracket with U

bolts and necessary kits for fitting on 2”NB stanchion pipe

stand or wall mount. (to be ordered seperately)

Option

Drain Port on instrument

side with drain plug Test Port on process side with plug

Accessory

Mounting Bolts – IS :

1364 – 1960 – 4 Nos

Interface seal – PTFE / VITON – 2 Nos

Interface seal – PTFE / VITON – 2 Nos